MA² Innovation Award from ÖVIA for Moldsonics and EREMA

Our pioneering innovation "PredictON: Plastification Unit - wear measurement as a service", in collaboration with EREMA Engineering Recycling Maschinen und Anlagenconvinced the jury and won this year's innovation prize of the ÖVIA (Austrian Association for Maintenance and Plant Management).

As the market leader in plastics recycling machinery and plant engineering, EREMA places a particular focus on condition monitoring and predictive maintenance solutions. These are driven forward in close partnership with innovative companies such as Moldsonics.

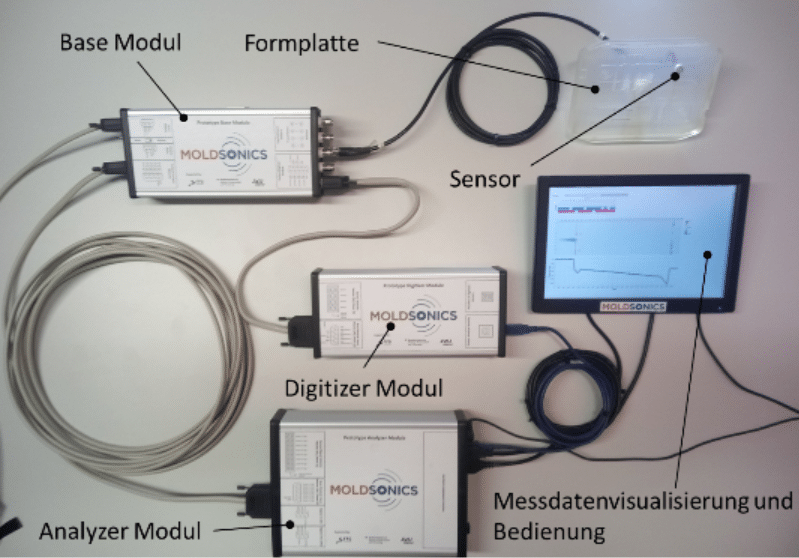

Our ultrasonic sensor solutions for the plastics processing industry provide a deep insight into the manufacturing process and offer the opportunity for optimization. We are setting completely new standards here with our innovative sensor technology. With SonicWear the wear condition can be determined during operation so that the system does not need to be shut down.

In this way, the customer can always keep an eye on the current status of all systems. Irregularities in the process can be detected immediately and appropriate measures can be taken, leading to sustainable cost optimization and increased efficiency.

The future vision for this innovation is the continuous (24/7) monitoring of recycling plants worldwide without the need for a technician to be on site.

Also the Austrian industry magazine also reported on our innovation. The special supplement is available to download here: