Markus Achleitner, State Councillor for Economics and Research, says: "Spin-offs are an ideal way to quickly make university research marketable. We want to further expand entrepreneurship in the university sector."

Those who make their research results usable as quickly as possible in the form of marketable innovations are ahead of the game. This is the case with Moldsonics, a spin-off of three researchers from Johannes Kepler University Linz (JKU), whose research innovation is making important improvements in the plastics industry possible. University spin-offs receive support not only from the state incubator tech2b, but also from the federal Research Promotion Agency (FFG).

"He or she who is first reaps the laurels. This is not only true in sports, but also in research. Therefore, as a successful business and science location, it is essential to transform research results into marketable innovations as quickly as possible. This was also emphasized by Prof. Dr. Teodoro Cocca as a key success factor for a region at last Friday's dialog on Upper Austria as a business location in Linz. The university spin-off Moldsonics is a prime example of how this can work," says Markus Achleitner, the provincial councilor for economics and research, referring to the successful university start-up.

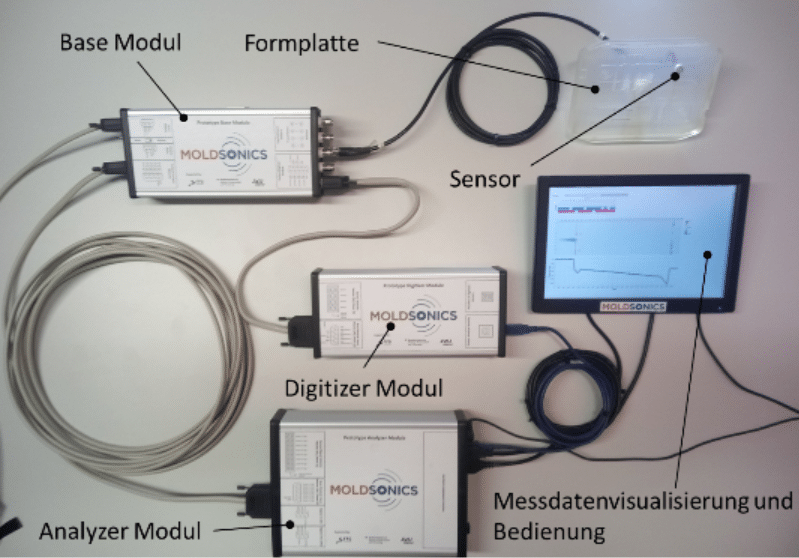

The three researchers Bernhard Praher, Klaus Straka and Thomas Mitterlehner of JKU enable with their research results a non-contact inspection or measurement of parameters during the injection molding process in the plastics industry, which they make available to companies through their spin-off Moldsonics. "The non-contact measurement eliminates the high wear of conventional detectors due to friction and heat. This makes the injection molding process more economically efficient, ecologically better because less scrap is produced, and overall improved because more accurate measured values are available. The end product is better overall," says Landesrat Achleitner, outlining the multiple advantages of ultrasound-based measurement.

"Spin-offs are an agile and cost-effective way to turn research results into marketable innovations. We already support them now through our state incubator tech2b. Due to the excellent research performance at JKU, there is still a lot of potential for university spin-offs in Upper Austria. The new start-up platform 'Hub'ert' provides an additional service tool for potential founders," says Economics Provincial Councilor Achleitner, who wants to further strengthen spin-offs in Upper Austria.

The Austrian Federal Research Promotion Agency (FFG) also sees great potential in university spin-offs: Last year, for the first time, it awarded fellowships to support start-ups by researchers employed at the university. The program was endowed with a total of 15 million euros. The founders of Moldsonics were also able to benefit from this.

"The transition from a university research environment to entrepreneurship poses many challenges. Here, as a budding young entrepreneur, one is very grateful for consulting services and financial support such as the FFG Spin-off Fellowship. The greatest joy, of course, is to see one's own research in the form of products on the market - that is the greatest appreciation for application-oriented research results. My team and I are therefore very proud to have been awarded an FFG Spin-off Fellowship and are now in the process of positioning our product in a sustainable and strategically correct way. This new career path away from a purely scientific career is a win-win situation for both the university and the researchers involved," explains Bernhard Praher, one of the three founders of Moldsonics.

Source: https://www.land-oberoesterreich.gv.at/225909.htm