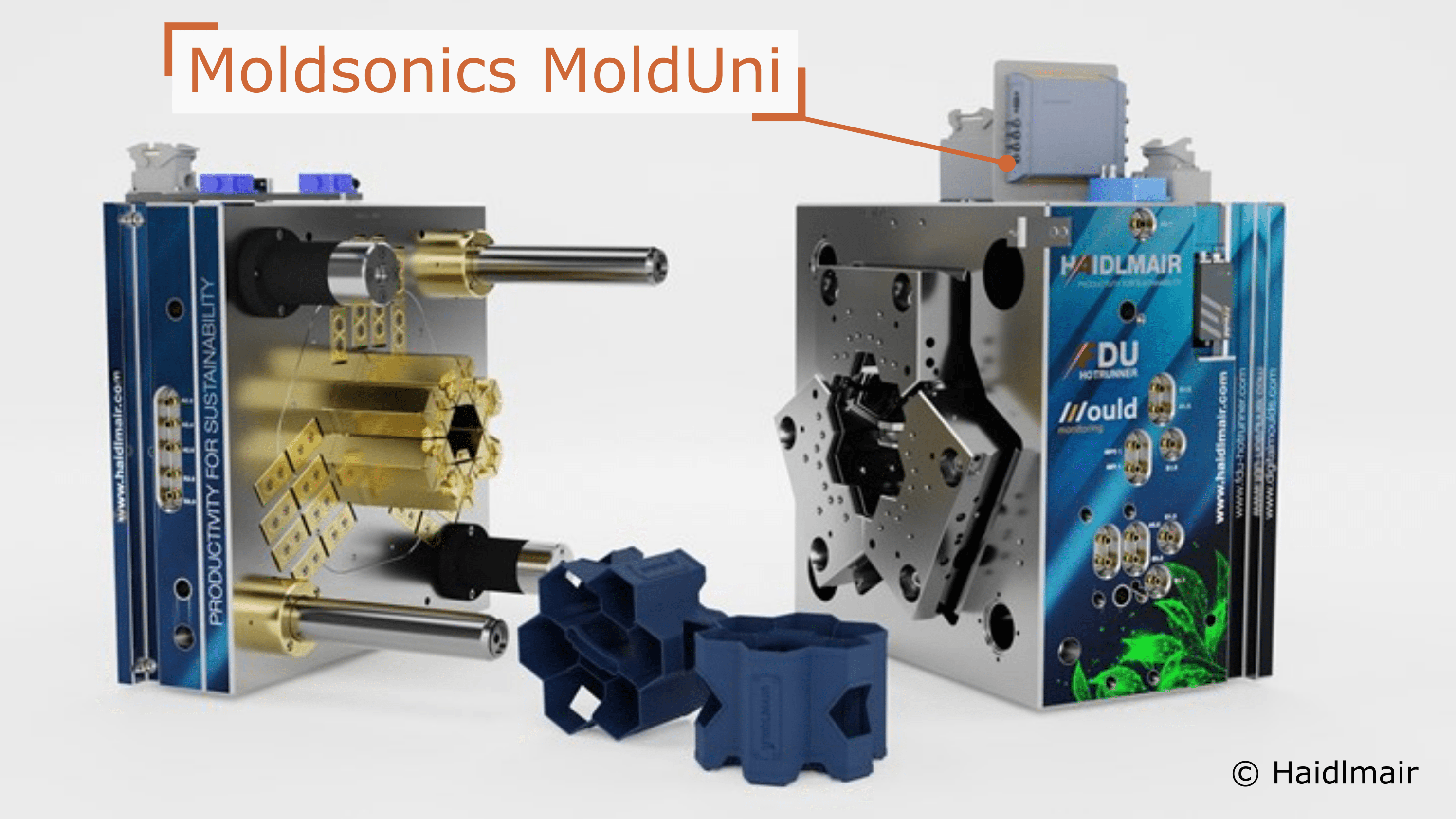

Next generation sensor technology.

Ultrasonic sensor technology for your plastics processing

Measure quality parameters without contact and without interfering with the process.

Increase your production efficiency with our ultrasonic sensor technology.

We are the manufacturer of a completely new ultrasonic sensor system for injection molds and plasticizing units, which makes it possible to measure quality parameters such as

- Flow fronts

- Flow velocities

- Solidification behavior

- Wear

contactless measurement.

Precise determination of these quality parameters leads toreduction of rejectsin the manufacturing of products,lower production costs,higher efficiencyandincreased productivity.

Advantages

non-contact

HIGH

HIGH

Why customers choose MoldSonics

Scrap reduction

Material and resource savings in the manufacturing of products leads to lower costs, higher efficiency, increased productivity and a better image of the company. In addition, there are positive effects on the environment by reducing energy consumption.

Process insight

Through the comprehensive process insight, you are able to identify and eliminate problems and bottlenecks that affect efficiency and quality by analyzing and monitoring the processes. As a result, productivity and profitability can be increased.

Robustness

The non-contact measurement method allows the sensor technology to be used even in the harshest environments and under adverse conditions. This can achieve higher reliability and efficiency in monitoring and controlling processes and save costs for repairs or replacement of sensors.

Reference

"Moldsonics' ultrasound-based sensor technology offers us completely new possibilities for analyzing processes in our filling operations and thus improving our tools."

We produce high quality sensor technology specifically designed to meet the requirements of industrial applications. Our sensors offer high precision, accuracy and reliability to ensure optimal control and monitoring of manufacturing processes.

In addition, our sensors are rugged and durable to ensure long-term, reliable performance in even the harshest environments.

News

MA² Innovation Award from ÖVIA for Moldsonics and EREMA

Our pioneering innovation "PredictON: Plastification Unit - Wear Measurement as a Service", in collaboration with EREMA Engineering Recycling Maschinen...

From Research to Innovation: Federal Minister Polaschek Visits JKU Spin-off Moldsonics

Another milestone in the development of our company Moldsonics was marked by the visit of the Austrian Federal Minister Martin Polaschek on...

Regional Minister for Economic Affairs Achleitner presents Winner diploma from tech2b to Moldsonics

Moldsonics successfully completes the tech2b Incubate program and receives the Winner Diploma from Achleitner. We at...

Do not miss any news from us:

©2023 - Moldsonics GmbH - All rights reserved