The quality of the injection molding process depends largely on the filling process and on the ability to produce a uniform flow front of the plastic in the mold.

An uneven flow front can lead to weak spots in the material, undesirable weld lines and rejected parts, which in turn reduces the profit when selling the end product.

Flow front detection challenges:

The detection of flow fronts in injection molds is a complex task.

An uneven flow front can be caused by these different influences:

- Changes in material properties

- Tool design

- Changes in the injection molding process

So far, there are various approaches for flow front detection, such as optical sensors, pressure sensors or temperature sensors. However, these methods have certain disadvantages, such as sensitivity to abrasive materials or limited dynamics.

A promising alternative to this is non-contact measurement using ultrasonic sensor technology.

How ultrasound-based flow front detection works:

Ultrasound-based flow front detection is based on the permanent emission of ultrasonic pulses in the direction of the cavity during the injection molding process.

With an empty cavity, 100 % of the ultrasonic energy is reflected at the steel/air interface. If the plastic now hits the measuring point, part of the ultrasonic energy is coupled into the plastic and precisely this difference is subsequently detected by the MoldFront sensor system.

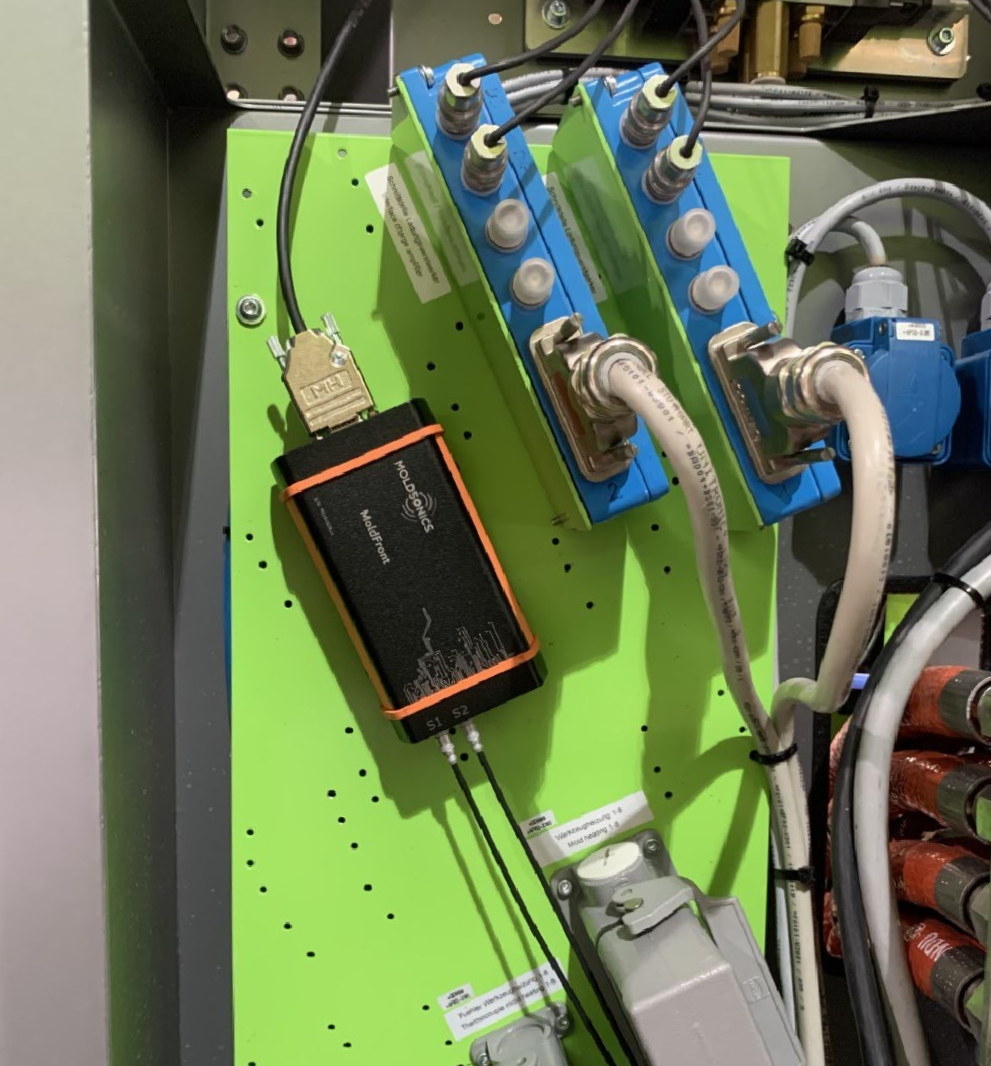

MoldFront electronics unit mounted on an injection molding machine

Click here to go to the sensory product mentioned:

Advantages of ultrasound-based flow front detection

Ultrasound-based flow front detection offers several advantages over other methods:

- Die Methode erfasst dynamisch und in Echtzeit Veränderungen der Fließfront, was eine schnelle Reaktionszeit im Bereich von < 5 Millisekunden ermöglicht.

- The method is robust against external influences such as abrasive media, high spray pressures or humidity.

- The method is independent of material and tool design and can therefore be applied to a wide range of applications.

- The method allows non-contact measurement at many different points in the mold, resulting in a high degree of design freedom.

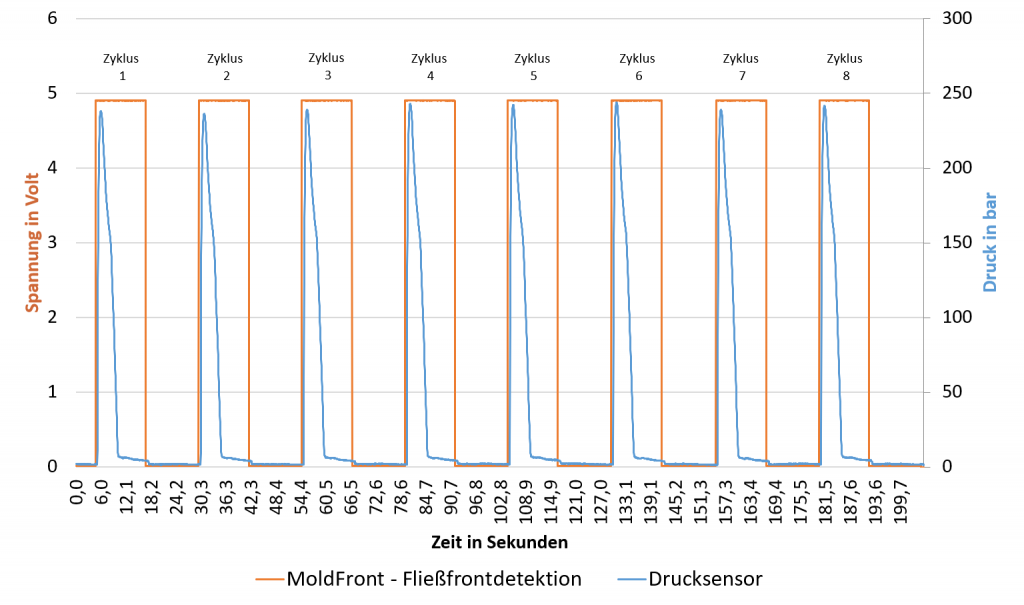

Comparison MoldFront flow front detection and pressure sensor technology

The use of pressure sensor technology is a common method for pressure measurement as well as detection of flow fronts in industry.

The MoldFront ultrasonic sensor technology can be used analogously. While the pressure sensor system measures the increase in pressure in the cavity in order to detect the flow front, the MoldFront ultrasonic sensor system uses density changes in the cavity. This accurately detects whether the steel/air or steel/plastic interface exists at the measurement point. This works equally well for other metals, such as aluminum or copper.

The great advantage of ultrasonic flow front detection is thus the possibility of measuring the flow front independently of the pressure conditions in the cavity. This means that no response pressure is required and the restriction to a predefined maximum pressure is also eliminated.

In addition, due to the non-invasive or non-contact measurement, ultrasonic flow front detection can also be used with abrasive media or vacuum applications without any problems.