matriq - component marking

Small effort - big effect

The groundbreaking DynamicMold® technology from matriq

Enables individual marking and coding

of plastic parts directly during the injection molding process.

Three powerful solutions for marking industrial plastic parts

Digital date on plastic components

Data matrix code on plastic components for full traceability

Data matrix code with individual branding on plastic components

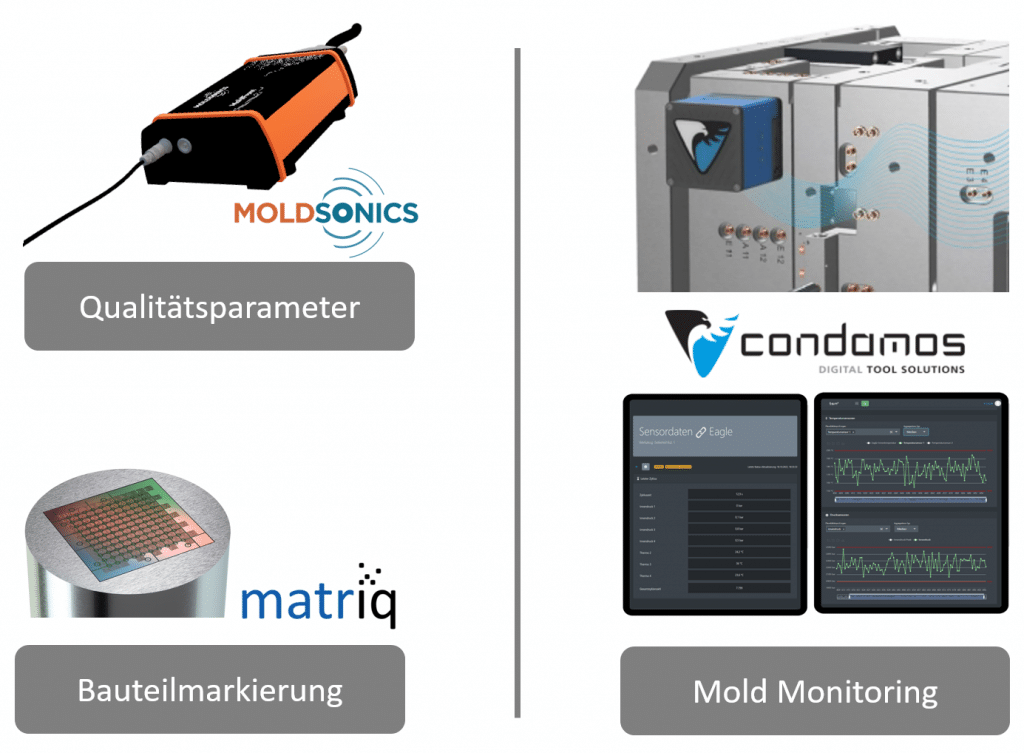

Application Moldsonics ultrasonic sensors

and matriq component marking

Mold monitoring

Mold Monitoring Systems enables the monitoring of molds and dies in component manufacturing to ensure that they are operating properly and delivering optimal product qualities.

Combining matriq sensors for part marking with ultrasonic sensors for measuring quality parameters in such a system provides an efficient solution for quality control, defect detection and traceability.

Questions and answers

.

Why is a component marking required?

Marking plastic products helps to track and trace your device for customization, identification, quality control and protection. It adds value to the individual part by linking information to the individual object.

In certain markets, labeling has even become mandatory: With unique device identification (UDI) enforced by regulations for an ever-growing number of products, especially in the MedTech and in-vitro diagnostics markets.

The reasons for this are obvious: quality control and traceability.

In other sectors, such as the automotive, electronics or packaging industries, a unique identification code on each part would make it easier to manage recalls and match them to their origin and manufacturing parameters.

Which plastic processing method is DynamicMold® technology compatible with?

DM technology was originally designed for marking in injection molding processes.

However, thanks to its versatility and plug-and-play nature, it is also compatible with other plastic molding processes such as thermoforming, blow molding and hot stamping. We are continuously optimizing our inserts to enable perfect integration into all these molding processes.

What type of products can the DM data set identify?

We can mark any product that is made entirely or partially of plastic (and results from a forming process). We offer our marking services for various applications: Medical device, life sciences, pharmaceutical packaging, automotive, consumer goods and industrial.

How can the code be read?

Products marked with DynamicMold have a code on their surface that creates an optical contrast - it is essentially direct part marking. Industrial code readers or standard handheld readers can read these DataMatrix codes on the plastic part.

The right lighting further enhances the contrast of the code. DataMatrix is an ISO standard 2D code and the algorithms for reading and interpreting these codes are widely used in the industry. Due to the individualization of each produced part, all process data (e.g. temperature, pressure) and origin parameters (raw material, supplier, machine, tool, cavity, etc.) of the specific product are combined in a cloud infrastructure, i.e. linked to the issued code.

By scanning the code (for DM-qode) along the value chain or by the end consumer, all important product information can be retrieved. This fully exploits the connectivity of our labeling solution along the entire value chain.

You still have questions?

Moldsonics GmbH

Hafenstraße 47-51

4020 Linz

AUSTRIA

Open address in Google Maps >>>

Don't miss any

news from us:

©2023 - Moldsonics GmbH - All rights reserved